The future of Amazon’s logistics system will without a doubt include AL and robotics, yet it’s an open inquiry at what point AI-powered machines will complete a majority of the work. As indicated by Scott Anderson, the company’s director of robotics satisfaction, the point at which an Amazon distribution is complete, start-to-end automated is n less than 10 years away. Anderson’s remarks, announced today by Reuters, feature the present pace of automation, even in conditions that are ready for robotic labor, similar to an Amazon warehouse.

As it stands today, robots in the workforce are capable mostly at explicit, repeatable assignments for which they are exactly programmed. To get the robot to accomplish something different takes costly, time-consuming reprogramming. And robots that can perform numerous different tasks and operate in dynamic conditions that require the robot to see and comprehend its surroundings are still immovably in the realm of research and experimental trials. Indeed, even the straightforward process of distinguished an object and lifting it up without having never observed that object before requires a progression of complex, sophisticated software and hardware that does not yet exist in a commercial fashion.

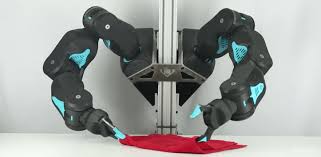

So while a robot can help manufacture a microchip and the body of a Tesla motor vehicle, it’s not equipped for doing human assignments that warehouse work requires. At Amazon facilities and other companies’ satisfaction centers, a bulk of the labor is still to a great extent done by human hands, since it’s hard to train robots to see the world and use robotic grippers with the dexterity of human workers.

In any case, as a major part of the continuous profound learning revolution that is accelerated the progress of AI inquires about in the last decade, robots are beginning to gain dimension of vision and motor control that are moving towards human-levels of sophistication. Amazon is one of the companies pioneering such robots, and it’s held a yearly purported picking challenge, after the warehouse term from picking up one item to move it to another piece of the logistics chain, to advance advances in the field.

Various different companies and research labs have been making progress on that front as well. UC Berkeley has a robotics lab that is gained significant progress in the field, and its new low-cost robot, a couple of humanoid arms constrained by a central system called Blue, can perform complex manual undertakings like the folding of a towel because of an AI-powered vision framework. Research lab OpenAI has comparatively been using an AI controlled technique known as reinforcement learning to show a robotic hand increasingly exact and elegant developments, the sort of motion that would be expected of a robot to duplicate a human in a warehouse. Related, a San Francisco-based startup, makes a robotic arm called kindred sort that it’s sent in warehouses for the retailer Gap that uses a blend of human piloting and automation to perform dynamic item picking.

As indicated by Reuters, Amazon has 110 warehouses in the US, 45 arranging centers, and about 50 delivery stations, all of which employ in excess of 125,000 full-time warehouse laborers. In any case, just a fraction of that work is performed by robots. At the present time, robots are essentially too imprecise and awkward and require a lot of training to be deployed on production line floors outside restricted use cases.

Also Read:

-

Facebook Anticipates on Competing With Google, Amazon and Apple by Offering Its Own AI Feature

-

Amazon Employees Had Access To Sensitive User Data Through Alexa

-

The Foldable Motorola Razr Looks Mind Blowing in These Leaked Renders

For example, Amazon uses little, Roomba shaped robots just called “drivers” for the most part to deliver huge stacks of items to human workers, by pursuing set paths around the warehouse. “In the present structure, the technology is constrained. The technology is a long way from the completely automated workstation that we would require,” Anderson told Reuters, which visited an Amazon warehouse in Baltimore earlier today.